Development Trends in the Standard Capacitor Industry

I. Introduction

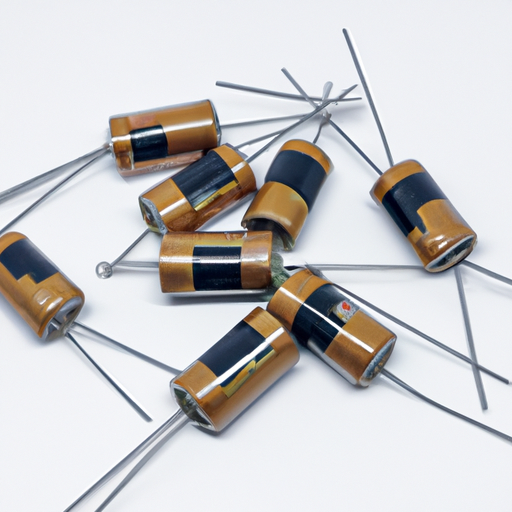

Standard capacitors are essential components in electronic circuits, serving as energy storage devices that can release energy when needed. They play a crucial role in various applications, from consumer electronics to automotive systems and industrial machinery. As technology continues to evolve, the standard capacitor industry is experiencing significant changes, driven by advancements in materials, manufacturing processes, and market demands. This blog post explores the development trends in the standard capacitor industry, providing insights into its historical context, current market landscape, emerging trends, technological innovations, challenges, and future outlook.

II. Historical Context

The evolution of capacitor technology dates back to the 18th century, with the invention of the Leyden jar, one of the first capacitors. Over the years, capacitor technology has undergone significant transformations, leading to the development of various types of capacitors, including electrolytic, ceramic, and film capacitors. Key milestones in the industry include the introduction of tantalum capacitors in the 1950s and the development of surface-mount technology (SMT) capacitors in the 1980s, which revolutionized the way capacitors are integrated into electronic devices.

Technological advancements have had a profound impact on the standard capacitor industry, enabling the production of smaller, more efficient, and higher-capacity capacitors. These innovations have paved the way for the widespread adoption of capacitors in various applications, enhancing device performance and reliability.

III. Current Market Landscape

A. Overview of the Global Standard Capacitor Market

The global standard capacitor market has witnessed substantial growth in recent years, driven by the increasing demand for electronic devices and the proliferation of smart technologies. According to market research, the standard capacitor market is projected to grow at a compound annual growth rate (CAGR) of approximately 6% over the next five years. Key players in the industry include companies like Murata Manufacturing, Vishay Intertechnology, and KEMET Corporation, which collectively hold a significant share of the market.

B. Applications of Standard Capacitors

Standard capacitors find applications across various sectors, including:

1. **Consumer Electronics**: Capacitors are integral to devices such as smartphones, tablets, and laptops, where they help stabilize voltage and filter signals.

2. **Automotive Industry**: With the rise of electric vehicles (EVs) and advanced driver-assistance systems (ADAS), capacitors are increasingly used for energy storage and power management.

3. **Industrial Applications**: Capacitors are employed in machinery and equipment for power factor correction, energy storage, and signal processing.

4. **Telecommunications**: Capacitors play a vital role in communication systems, ensuring signal integrity and power stability.

C. Regulatory and Standardization Bodies

Regulatory and standardization bodies, such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE), influence the standard capacitor industry by establishing guidelines and standards for performance, safety, and environmental impact. Compliance with these standards is essential for manufacturers to ensure product quality and reliability.

IV. Emerging Trends in the Standard Capacitor Industry

A. Miniaturization and Increased Capacitance

One of the most significant trends in the standard capacitor industry is the miniaturization of capacitors while simultaneously increasing their capacitance. Advances in materials and manufacturing processes, such as the use of high-k dielectric materials, have enabled the production of smaller capacitors with higher energy storage capabilities. This trend is particularly important for modern electronic devices, which demand compact components without compromising performance.

B. Development of High-Performance Capacitors

The demand for high-performance capacitors is on the rise, particularly in high-frequency and high-voltage applications. These capacitors are designed to withstand extreme conditions and deliver superior performance. Industries such as telecommunications and aerospace are increasingly relying on high-performance capacitors to meet their stringent requirements.

C. Integration with Smart Technologies

As the Internet of Things (IoT) continues to expand, the role of capacitors in smart technologies is becoming more prominent. Capacitors are essential for energy storage and management in IoT devices, enabling them to operate efficiently and reliably. Additionally, capacitors are being integrated into smart grid applications, where they help stabilize power supply and improve energy efficiency.

D. Sustainability and Eco-Friendly Practices

Sustainability is a growing concern in the capacitor industry, prompting manufacturers to adopt eco-friendly practices. The use of recyclable materials in capacitor production and the implementation of energy-efficient manufacturing processes are becoming standard practices. This trend not only reduces the environmental impact of capacitor production but also aligns with the increasing consumer demand for sustainable products.

V. Technological Innovations

A. New Materials and Their Impact on Capacitor Performance

The development of new dielectric and conductive materials is revolutionizing capacitor performance. High-k dielectric materials, for instance, allow for greater capacitance in smaller packages, while advanced conductive materials enhance the efficiency and reliability of capacitors. These innovations are crucial for meeting the demands of modern electronic applications.

B. Advances in Manufacturing Techniques

Manufacturing techniques are also evolving, with the adoption of 3D printing and additive manufacturing processes. These technologies enable the production of complex capacitor designs that were previously impossible to achieve. Additionally, automation and smart manufacturing practices are streamlining production processes, reducing costs, and improving product quality.

C. Research and Development Initiatives

Collaboration between academia and industry is driving research and development initiatives in the capacitor sector. Government funding and support for innovation are also playing a crucial role in advancing capacitor technology. These initiatives are focused on developing next-generation capacitors that meet the evolving needs of various industries.

VI. Challenges Facing the Standard Capacitor Industry

Despite the positive trends, the standard capacitor industry faces several challenges. Supply chain disruptions, exacerbated by global events such as the COVID-19 pandemic, have impacted the availability of raw materials and components. Additionally, competition from alternative technologies, such as supercapacitors and batteries, poses a threat to traditional capacitors.

Regulatory challenges and compliance issues also present hurdles for manufacturers, as they must navigate complex regulations while ensuring product quality. Furthermore, market volatility and economic factors can influence demand and pricing, creating uncertainty in the industry.

VII. Future Outlook

The future of the standard capacitor industry looks promising, with predictions for continued market growth and technological advancements. As consumer demand shifts towards more compact and efficient electronic devices, the need for innovative capacitor solutions will only increase. Additionally, the integration of capacitors into emerging technologies, such as renewable energy systems and electric vehicles, will further drive demand.

The role of standard capacitors in future technologies will be pivotal, as they continue to support the development of smarter, more efficient electronic systems. Manufacturers that prioritize innovation, sustainability, and adaptability will be well-positioned to thrive in this evolving landscape.

VIII. Conclusion

In summary, the standard capacitor industry is undergoing significant transformations driven by technological advancements, market demands, and sustainability initiatives. The trends of miniaturization, high-performance capacitors, integration with smart technologies, and eco-friendly practices are shaping the future of the industry. As challenges arise, adaptability and innovation will be key to navigating the evolving landscape. The importance of standard capacitors in various applications cannot be overstated, and their continued development will play a crucial role in the advancement of modern technology.

IX. References

1. Academic journals and articles on capacitor technology and market trends.

2. Industry reports and market analyses from reputable sources.

3. Relevant standards and regulations from organizations such as the IEC and IEEE.

This blog post provides a comprehensive overview of the development trends in the standard capacitor industry, highlighting the historical context, current market dynamics, emerging trends, technological innovations, challenges, and future outlook. As the industry continues to evolve, staying informed about these trends will be essential for stakeholders and consumers alike.