How Should Spot Start Capacitors Be Selected?

I. Introduction

In the world of electronics, capacitors play a crucial role in various applications, particularly in starting motors and stabilizing power supplies. Among these, spot start capacitors are essential components that ensure reliable operation in specific scenarios. This article will delve into the selection process for spot start capacitors, emphasizing their importance, functionality, and the key parameters to consider for optimal performance.

II. Understanding Spot Start Capacitors

A. Function and Purpose

Spot start capacitors are designed to provide a temporary boost of electrical energy to start motors or to stabilize voltage in power supply circuits. They store electrical energy and release it quickly, which is vital in applications where immediate power is required.

B. Applications in Various Industries

These capacitors find applications across multiple industries, including automotive, HVAC, and consumer electronics. For instance, in HVAC systems, spot start capacitors help kickstart compressor motors, while in automotive applications, they assist in starting the engine.

C. Types of Spot Start Capacitors

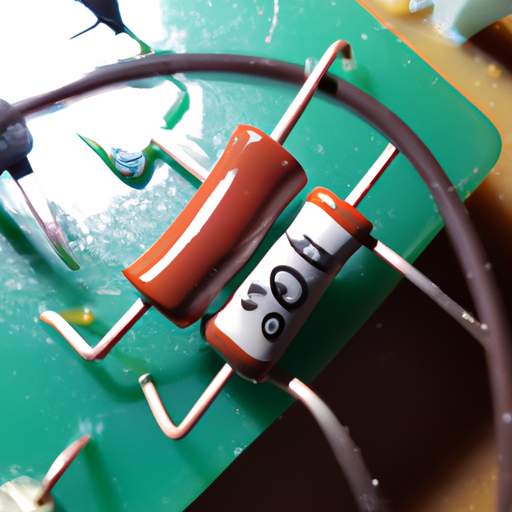

There are several types of capacitors used for spot starting applications, each with unique characteristics:

1. **Electrolytic Capacitors**: Known for their high capacitance values, these capacitors are often used in power supply circuits.

2. **Film Capacitors**: These capacitors are favored for their stability and low loss, making them suitable for audio applications.

3. **Ceramic Capacitors**: With their small size and reliability, ceramic capacitors are commonly used in various electronic devices.

4. **Tantalum Capacitors**: These capacitors offer high capacitance in a small package and are used in applications requiring compact designs.

III. Key Parameters for Selection

When selecting spot start capacitors, several key parameters must be considered to ensure optimal performance.

A. Voltage Rating

1. Importance of Voltage Rating

The voltage rating of a capacitor indicates the maximum voltage it can handle without failing. Selecting a capacitor with an appropriate voltage rating is crucial to prevent breakdown and ensure longevity.

2. How to Determine Required Voltage

To determine the required voltage rating, consider the maximum voltage that the capacitor will experience in the circuit. It is advisable to choose a capacitor with a voltage rating at least 20% higher than the maximum operating voltage.

B. Capacitance Value

1. Understanding Capacitance

Capacitance is the ability of a capacitor to store electrical energy. It is measured in farads (F), with microfarads (µF) being the most common unit for spot start capacitors.

2. Calculating Required Capacitance

The required capacitance can be calculated based on the specific application. For motor start applications, the capacitance value is often determined by the motor's specifications and the starting torque required.

C. Temperature Rating

1. Impact of Temperature on Performance

Temperature can significantly affect a capacitor's performance and lifespan. High temperatures can lead to increased leakage current and reduced capacitance.

2. Selecting Temperature Ratings for Different Environments

When selecting a capacitor, consider the operating environment. For high-temperature applications, choose capacitors with higher temperature ratings, typically ranging from -40°C to +125°C.

D. Ripple Current Rating

1. Definition and Importance

Ripple current refers to the AC component of the current flowing through a capacitor. The ripple current rating indicates the maximum AC current the capacitor can handle without overheating.

2. How to Calculate Ripple Current

To calculate the ripple current, consider the load conditions and the frequency of the AC signal. Ensure that the selected capacitor can handle the calculated ripple current to avoid failure.

E. Equivalent Series Resistance (ESR)

1. Definition and Significance

ESR is the internal resistance of a capacitor that affects its efficiency and heat generation. A lower ESR is generally preferred for applications requiring high-frequency performance.

2. Selecting Capacitors with Appropriate ESR

When selecting capacitors, consider the ESR values specified by the manufacturer. For high-frequency applications, choose capacitors with low ESR to minimize energy loss.

IV. Application-Specific Considerations

A. Motor Start Applications

1. Requirements for Motor Start Capacitors

Motor start capacitors must provide a high starting torque and be able to handle the inrush current when the motor starts.

2. Selection Criteria for Motor Applications

When selecting capacitors for motor applications, consider the motor's voltage, capacitance requirements, and the expected operating temperature.

B. Power Supply Applications

1. Capacitor Role in Power Supplies

In power supply circuits, capacitors stabilize voltage and filter out noise. They are essential for maintaining a steady output voltage.

2. Key Selection Factors for Power Supply Capacitors

For power supply applications, focus on capacitance value, voltage rating, and ripple current rating to ensure reliable performance.

C. Audio and Signal Processing Applications

1. Importance of Quality in Audio Applications

In audio applications, the quality of capacitors can significantly impact sound performance. High-quality capacitors minimize distortion and improve audio clarity.

2. Selection Criteria for Audio Capacitors

When selecting capacitors for audio applications, prioritize low ESR, high capacitance, and stability over temperature variations.

V. Environmental and Regulatory Considerations

A. Compliance with Industry Standards

1. Overview of Relevant Standards (e.g., UL, IEC)

Compliance with industry standards ensures that capacitors meet safety and performance requirements. Familiarize yourself with relevant standards such as UL and IEC.

2. Importance of Certification

Choosing certified capacitors provides assurance of quality and reliability, which is crucial for safety-critical applications.

B. Environmental Impact

1. RoHS Compliance

RoHS (Restriction of Hazardous Substances) compliance is essential for minimizing environmental impact. Ensure that selected capacitors meet RoHS standards.

2. End-of-Life Considerations

Consider the end-of-life disposal of capacitors. Opt for manufacturers that provide guidance on recycling and disposal to minimize environmental impact.

VI. Testing and Validation

A. Importance of Testing Selected Capacitors

Testing is crucial to validate the performance of selected capacitors. It ensures that they meet the required specifications and can operate reliably in their intended applications.

B. Common Testing Methods

1. Capacitance Measurement

Capacitance measurement verifies that the capacitor meets its specified capacitance value.

2. ESR Measurement

ESR measurement assesses the internal resistance of the capacitor, ensuring it is within acceptable limits.

3. Voltage and Temperature Testing

Testing capacitors under various voltage and temperature conditions helps validate their performance in real-world applications.

C. Validation in Real-World Applications

Conducting tests in actual operating conditions is essential to ensure that the selected capacitors perform as expected in their intended applications.

VII. Conclusion

In conclusion, selecting the right spot start capacitors is critical for ensuring the reliability and efficiency of electrical systems. By understanding the various types of capacitors, key selection parameters, and application-specific considerations, engineers and technicians can make informed decisions. Proper selection not only enhances performance but also contributes to the longevity of the components and systems involved. As technology continues to evolve, ongoing research and learning in capacitor technology will remain essential for optimizing electronic designs.

VIII. References

A. Suggested Reading and Resources

- "Capacitor Technology: A Comprehensive Guide" by John Doe

- "Understanding Capacitors: A Practical Approach" by Jane Smith

B. Industry Standards and Guidelines

- UL Standards for Capacitors

- IEC 60384: Fixed Capacitors for Use in Electronic Equipment

C. Manufacturer Specifications and Data Sheets

- Manufacturer A: Capacitor Data Sheets

- Manufacturer B: Technical Specifications for Spot Start Capacitors

By following this guide, you can ensure that your selection of spot start capacitors meets the demands of your specific applications, leading to improved performance and reliability.