CORE_COMPETENCE

Product_Leaders

index_more

index_more_content

info_item01

info_item_content01

info_item02

info_item_content02

info_item03

info_item_content03

info_item04

info_item_content04

NEWS

NEWS

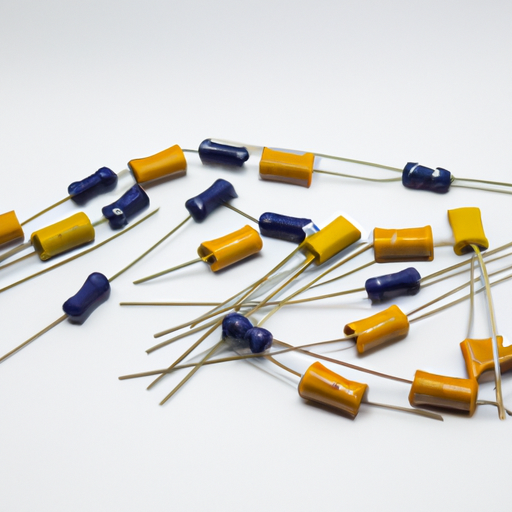

Similar recommendations for resistor L components

Similar Recommendations for Resistor L Components

I. Introduction

In the world of electronics, components play a crucial role in the functionality and efficiency of devices. Among these components, resistor L components are particularly significant. These resistors are essential for controlling current flow, dividing voltages, and ensuring that electronic circuits operate smoothly. This article aims to provide insights and recommendations for similar resistor L components, helping engineers and hobbyists alike make informed decisions when selecting resistors for their projects.

II. Understanding Resistor L Components

A. What are Resistor L Components?

Resistor L components, often referred to simply as resistors, are passive electronic components that resist the flow of electric current. They are characterized by their resistance value, which is measured in ohms (Ω). Resistor L components are integral to various electronic applications, serving multiple functions that enhance circuit performance.

1. Definition and Functionality

The primary function of a resistor is to limit the amount of current that can flow through a circuit. By doing so, they help protect sensitive components from damage due to excessive current. Resistors can also be used to create voltage dividers, which allow for the distribution of voltage across different parts of a circuit.

2. Types of Resistor L Components

There are several types of resistor L components, each designed for specific applications. The most common types include:

Carbon Film Resistors: Known for their stability and low cost, these resistors are widely used in general-purpose applications.

Metal Film Resistors: These resistors offer better precision and stability compared to carbon film resistors, making them suitable for high-frequency applications.

Wirewound Resistors: Constructed by winding a metal wire around a ceramic or fiberglass core, these resistors can handle high power ratings and are often used in power applications.

Surface Mount Resistors: These resistors are designed for surface mounting on printed circuit boards (PCBs) and are favored in modern electronics due to their compact size.

B. Key Characteristics

When selecting resistor L components, several key characteristics must be considered:

1. Resistance Value

The resistance value is the most critical specification, as it determines how much current will flow through the resistor. It is essential to choose a resistor with the appropriate resistance value for the specific application.

2. Tolerance

Tolerance indicates how much the actual resistance can vary from the stated value. A lower tolerance percentage means higher precision, which is crucial in applications where accuracy is paramount.

3. Power Rating

The power rating, measured in watts (W), indicates the maximum amount of power a resistor can dissipate without overheating. Selecting a resistor with an appropriate power rating is vital to ensure reliability and prevent failure.

4. Temperature Coefficient

The temperature coefficient measures how much the resistance changes with temperature. This characteristic is important in applications where temperature fluctuations are expected, as it can affect circuit performance.

III. Applications of Resistor L Components

A. Common Uses in Electronic Devices

Resistor L components are ubiquitous in electronic devices, serving various functions:

1. Signal Processing

In signal processing applications, resistors are used to filter signals, attenuate noise, and ensure signal integrity. They play a vital role in audio equipment, communication devices, and other electronic systems.

2. Voltage Division

Resistors are commonly used in voltage divider circuits, where they help distribute voltage across different components. This is particularly useful in sensor applications, where specific voltage levels are required for accurate readings.

3. Current Limiting

Resistors are often employed to limit current flow to sensitive components, such as LEDs. By controlling the current, resistors help prevent damage and ensure optimal performance.

B. Industry-Specific Applications

Different industries utilize resistor L components for various applications:

1. Consumer Electronics

In consumer electronics, resistors are found in devices such as televisions, smartphones, and audio systems. They help manage power consumption and ensure reliable operation.

2. Automotive

In the automotive industry, resistors are used in various applications, including engine control units, sensor systems, and lighting. They play a crucial role in ensuring the safety and efficiency of modern vehicles.

3. Telecommunications

Telecommunication devices rely on resistors for signal processing and voltage regulation. They are essential for maintaining the integrity of data transmission and ensuring reliable communication.

IV. Similar Recommendations for Resistor L Components

A. Identifying Similar Components

When looking for alternatives to resistor L components, it is essential to identify components that share similar characteristics. The following criteria can help in this process:

1. Criteria for Similarity

Resistance Value: Ensure that the alternative resistor has a comparable resistance value to the original component.

Power Rating: The power rating should match or exceed the requirements of the application.

Physical Size: Consider the physical dimensions of the resistor, especially in compact designs.

2. Commonly Used Resistor L Components

Some commonly used resistor L components include:

Standard Carbon Film Resistors: Affordable and widely available, suitable for general applications.

Precision Metal Film Resistors: Ideal for applications requiring high accuracy and stability.

High-Power Wirewound Resistors: Suitable for applications with high power demands.

B. Recommended Alternatives

When seeking alternatives to resistor L components, consider the following options:

1. Carbon Film Resistors

These resistors are cost-effective and suitable for a wide range of applications. They offer decent performance for general-purpose use.

2. Metal Film Resistors

For applications requiring higher precision, metal film resistors are an excellent choice. They provide better stability and lower noise levels compared to carbon film resistors.

3. Wirewound Resistors

If your application involves high power, wirewound resistors are recommended. They can handle significant power loads and are often used in power supply circuits.

4. Surface Mount Resistors

For modern electronic designs, surface mount resistors are ideal due to their compact size and ease of integration into PCBs.

C. Comparison of Recommended Components

When comparing recommended components, consider the following factors:

1. Performance Metrics

Evaluate the performance metrics of each resistor type, including tolerance, temperature coefficient, and noise levels. This will help determine which component best suits your application.

2. Cost Considerations

Cost is always a factor in component selection. While some resistors may offer superior performance, they may also come at a higher price. Balance performance needs with budget constraints.

3. Availability

Ensure that the recommended components are readily available from suppliers. Availability can impact project timelines and overall efficiency.

V. Factors to Consider When Choosing Resistor L Components

A. Application Requirements

When selecting resistor L components, consider the specific requirements of your application:

1. Load Conditions

Understand the load conditions the resistor will face, including current levels and voltage ratings. This information is crucial for selecting the appropriate resistor type.

2. Environmental Factors

Consider the environmental conditions in which the resistor will operate. Factors such as temperature, humidity, and exposure to chemicals can affect performance and longevity.

B. Reliability and Longevity

Choose resistors from reputable manufacturers known for quality assurance. Reliability is critical in electronic applications, and selecting high-quality components can prevent failures and enhance longevity.

C. Manufacturer Reputation and Quality Assurance

Research the reputation of manufacturers and their quality assurance processes. Opt for components from trusted brands to ensure consistent performance and reliability.

VI. Conclusion

In summary, resistor L components are vital for the functionality of electronic circuits. Understanding their characteristics, applications, and available alternatives is essential for making informed decisions. When selecting resistors, consider factors such as resistance value, power rating, and environmental conditions. By following the recommendations outlined in this article, engineers and hobbyists can enhance their projects and ensure optimal performance.

VII. References

For further reading on resistor L components and electronics, consider the following resources:

- "The Art of Electronics" by Paul Horowitz and Winfield Hill

- "Electronic Components: A Complete Reference for Project Builders" by Mark J. Balch

- Online resources such as Digi-Key, Mouser Electronics, and other electronic component suppliers.

2024-11-10

0

What are the advantages of strip resistor products?

What are the Advantages of Strip Resistor Products?

I. Introduction

In the world of electronics, resistors play a crucial role in controlling current flow, dividing voltages, and protecting sensitive components. Among the various types of resistors available, strip resistors have gained significant attention due to their unique characteristics and advantages. This blog post will explore the advantages of strip resistor products, shedding light on their construction, types, and applications in modern electronics.

II. Understanding Strip Resistors

A. Description and Construction of Strip Resistors

Strip resistors are specialized resistive components characterized by their elongated, flat design. They are typically constructed from a resistive material that is deposited onto a substrate, which can be made from various materials such as ceramic, glass, or polymer. The resistive layer is often created using thin or thick film technology, allowing for precise control over the resistance value.

1. **Materials Used**: Common materials for strip resistors include metal oxides, carbon, and conductive polymers. The choice of material affects the resistor's performance, including its temperature coefficient and stability.

2. **Design Features**: Strip resistors are designed to maximize surface area, which enhances heat dissipation and allows for better thermal management. Their flat profile also makes them suitable for surface-mount technology (SMT), enabling easy integration into compact electronic devices.

B. Types of Strip Resistors

Strip resistors can be categorized into two main types:

1. **Thin Film Strip Resistors**: These resistors are made by depositing a thin layer of resistive material onto a substrate. They offer high precision and low temperature coefficients, making them ideal for applications requiring accurate resistance values.

2. **Thick Film Strip Resistors**: Thick film resistors are created by screen printing a thicker layer of resistive material. They are generally more robust and can handle higher power levels, making them suitable for a wider range of applications.

C. Comparison with Other Resistor Types

Compared to traditional wire-wound or carbon film resistors, strip resistors offer several advantages, including better thermal performance, higher precision, and a more compact form factor. Their design allows for greater flexibility in circuit layouts, making them a preferred choice in modern electronic applications.

III. Advantages of Strip Resistor Products

A. High Precision and Accuracy

One of the standout features of strip resistors is their high precision and accuracy.

1. **Tolerance Levels**: Strip resistors can achieve very low tolerance levels, often as tight as ±0.1%. This precision is essential in applications where exact resistance values are critical, such as in precision measurement devices.

2. **Temperature Coefficient of Resistance (TCR)**: Strip resistors typically exhibit low TCR values, meaning their resistance changes minimally with temperature fluctuations. This stability is vital for maintaining performance in varying environmental conditions.

B. Compact Size and Space Efficiency

As electronic devices continue to shrink in size, the demand for compact components has increased.

1. **Design Flexibility in Circuit Layouts**: The flat, elongated design of strip resistors allows for efficient use of space on printed circuit boards (PCBs). This flexibility enables engineers to design more compact and efficient circuits.

2. **Benefits in Miniaturized Electronic Devices**: In applications such as smartphones, wearables, and IoT devices, where space is at a premium, strip resistors provide an ideal solution without compromising performance.

C. Enhanced Thermal Management

Effective thermal management is crucial in electronic design to ensure reliability and performance.

1. **Heat Dissipation Characteristics**: The larger surface area of strip resistors facilitates better heat dissipation compared to traditional resistor types. This characteristic helps prevent overheating, which can lead to component failure.

2. **Impact on Reliability and Performance**: By managing heat effectively, strip resistors contribute to the overall reliability of electronic devices, ensuring consistent performance over time.

D. Wide Range of Resistance Values

Strip resistors are available in a broad spectrum of resistance values, making them versatile for various applications.

1. **Customization Options**: Many manufacturers offer customization options for strip resistors, allowing engineers to specify exact resistance values and tolerances to meet specific application needs.

2. **Applications in Various Industries**: From consumer electronics to automotive and industrial applications, the wide range of available resistance values makes strip resistors suitable for diverse uses.

E. Improved Stability and Reliability

Stability and reliability are paramount in electronic components, and strip resistors excel in these areas.

1. **Long-Term Performance**: Strip resistors are designed to maintain their performance characteristics over extended periods, reducing the need for frequent replacements.

2. **Resistance to Environmental Factors**: Many strip resistors are engineered to withstand harsh environmental conditions, including humidity, temperature extremes, and mechanical stress, making them suitable for demanding applications.

F. Cost-Effectiveness

While the initial cost of strip resistors may be higher than some traditional resistor types, their long-term benefits often outweigh the initial investment.

1. **Manufacturing Efficiency**: The production processes for strip resistors, particularly thin film technology, can be highly efficient, leading to lower manufacturing costs in high-volume applications.

2. **Long-Term Savings in Applications**: The durability and reliability of strip resistors can result in significant cost savings over time, as they reduce the frequency of replacements and maintenance.

IV. Applications of Strip Resistors

Strip resistors find applications across various industries, including:

A. Consumer Electronics

In devices such as smartphones, tablets, and laptops, strip resistors are used for voltage division, current limiting, and signal conditioning.

B. Automotive Industry

Strip resistors are employed in automotive electronics for applications like sensor signal processing, power management, and control systems, where precision and reliability are critical.

C. Industrial Automation

In industrial settings, strip resistors are used in control systems, robotics, and automation equipment, where their stability and accuracy enhance operational efficiency.

D. Telecommunications

Telecommunication equipment relies on strip resistors for signal integrity and power management, ensuring reliable communication in various applications.

E. Medical Devices

In the medical field, strip resistors are used in diagnostic equipment, monitoring devices, and therapeutic instruments, where precision and reliability are paramount for patient safety.

V. Challenges and Considerations

While strip resistors offer numerous advantages, there are also challenges and considerations to keep in mind.

A. Limitations of Strip Resistors

Strip resistors may not be suitable for all applications, particularly those requiring very high power ratings or extreme environmental conditions. Understanding the limitations is essential for proper application.

B. Factors to Consider When Selecting Strip Resistors

1. **Application Requirements**: Engineers must consider the specific requirements of their application, including resistance value, tolerance, and power rating.

2. **Environmental Conditions**: The operating environment can significantly impact resistor performance. Factors such as temperature, humidity, and mechanical stress should be evaluated when selecting strip resistors.

VI. Conclusion

In summary, strip resistors offer a range of advantages that make them an essential component in modern electronics. Their high precision, compact size, enhanced thermal management, and wide range of resistance values contribute to their growing popularity across various industries. As technology continues to evolve, the demand for reliable and efficient components like strip resistors will only increase.

Looking ahead, advancements in strip resistor technology are likely to focus on improving performance, reducing costs, and expanding their applications. As engineers and designers continue to push the boundaries of electronic design, strip resistors will remain a vital part of the equation, ensuring that devices operate reliably and efficiently in an ever-changing technological landscape.

VII. References

1. "Resistor Technology: A Comprehensive Guide," Electronics Weekly.

2. "Understanding Resistor Types and Their Applications," IEEE Spectrum.

3. "The Role of Resistors in Electronic Circuits," Journal of Electronic Materials.

4. "Advancements in Thin Film Resistor Technology," Journal of Applied Physics.

5. "Thermal Management in Electronics: Best Practices," Electronics Cooling Magazine.

This blog post aims to provide a comprehensive overview of the advantages of strip resistor products, highlighting their significance in various electronic applications while addressing potential challenges and considerations for their use.

2024-11-09

0

What are the development trends in the chip adjustable resistor industry?

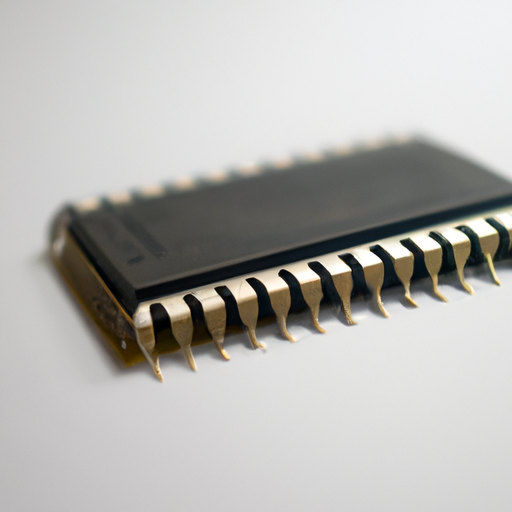

Development Trends in the Chip Adjustable Resistor Industry

I. Introduction

In the rapidly evolving world of electronics, chip adjustable resistors play a crucial role in enhancing the performance and functionality of various devices. These components, which allow for variable resistance in electronic circuits, are essential for applications ranging from consumer electronics to automotive systems. As the demand for more sophisticated and compact electronic devices continues to rise, the chip adjustable resistor market is witnessing significant growth and innovation. This blog post explores the development trends in the chip adjustable resistor industry, highlighting historical context, current market dynamics, technological advancements, manufacturing innovations, environmental considerations, and future predictions.

II. Historical Context

The journey of resistors in electronic components has been marked by continuous innovation. Traditional resistors, often bulky and less efficient, have gradually transitioned to chip adjustable resistors, which offer enhanced performance in a compact form factor. The introduction of chip technology in the 1980s marked a significant milestone, allowing for greater precision and reliability in electronic circuits. Over the years, advancements in materials and manufacturing processes have further propelled the development of chip adjustable resistors, making them indispensable in modern electronics.

III. Current Market Landscape

A. Overview of the Chip Adjustable Resistor Market

The chip adjustable resistor market has experienced substantial growth, driven by the increasing demand for miniaturized electronic devices. According to recent market analyses, the global chip adjustable resistor market is projected to reach several billion dollars by the mid-2020s, with a compound annual growth rate (CAGR) of over 6%. Key players in the industry include established semiconductor manufacturers and emerging startups, all vying for a share of this lucrative market.

B. Applications of Chip Adjustable Resistors

Chip adjustable resistors find applications across various sectors:

1. **Consumer Electronics**: From smartphones to smart home devices, adjustable resistors are integral in managing power consumption and signal processing.

2. **Automotive Industry**: In modern vehicles, these resistors are used in advanced driver-assistance systems (ADAS) and infotainment systems, enhancing safety and user experience.

3. **Industrial Applications**: Adjustable resistors are employed in automation and control systems, where precise resistance values are crucial for optimal performance.

4. **Telecommunications**: In communication devices, they help in signal conditioning and impedance matching, ensuring reliable data transmission.

IV. Technological Advancements

A. Miniaturization and Integration

One of the most significant trends in the chip adjustable resistor industry is the push towards miniaturization. As electronic devices become smaller and more complex, the demand for compact components has surged. Manufacturers are focusing on developing chip adjustable resistors with smaller form factors, allowing for greater integration within circuit boards. This trend is complemented by the integration of adjustable resistors with other components, such as capacitors and inductors, leading to more efficient circuit designs.

B. Enhanced Performance Characteristics

Technological advancements have also led to improved performance characteristics of chip adjustable resistors. Manufacturers are investing in research and development to enhance accuracy and stability, ensuring that these components can operate effectively under varying conditions. Additionally, improvements in temperature coefficients have made it possible for adjustable resistors to maintain consistent performance across a wider temperature range, which is particularly important in automotive and industrial applications.

C. Smart Resistors and IoT Integration

The rise of the Internet of Things (IoT) has opened new avenues for chip adjustable resistors. The development of smart adjustable resistors, which can communicate with other devices and systems, is becoming increasingly prevalent. These smart resistors can automatically adjust their resistance based on real-time data, optimizing performance and energy efficiency. As IoT applications continue to expand, the demand for intelligent components like smart adjustable resistors is expected to grow significantly.

V. Manufacturing Innovations

A. Advances in Fabrication Techniques

The manufacturing landscape for chip adjustable resistors is evolving, with advances in fabrication techniques playing a pivotal role. Thin-film and thick-film technologies are being refined to produce resistors with higher precision and reliability. Additionally, the advent of 3D printing and additive manufacturing is revolutionizing the production process, allowing for greater design flexibility and reduced lead times.

B. Cost Reduction Strategies

As competition intensifies in the chip adjustable resistor market, manufacturers are implementing cost reduction strategies to maintain profitability. Economies of scale are being leveraged to lower production costs, while material innovations are being explored to enhance performance without significantly increasing expenses. These strategies are crucial for ensuring that chip adjustable resistors remain accessible to a wide range of applications.

VI. Environmental and Regulatory Considerations

A. Sustainability Trends in the Electronics Industry

As the electronics industry faces increasing scrutiny regarding its environmental impact, sustainability trends are becoming more prominent. Manufacturers are exploring eco-friendly materials and processes to reduce their carbon footprint. The use of recyclable materials and the implementation of sustainable manufacturing practices are gaining traction, aligning with the global push for greener electronics.

B. Compliance with Global Regulations

Compliance with global regulations, such as the Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) directives, is essential for manufacturers of chip adjustable resistors. These regulations aim to minimize the environmental impact of electronic waste and ensure the safety of consumers. Adapting manufacturing practices to meet these standards is not only a legal requirement but also a competitive advantage in the market.

VII. Future Trends and Predictions

A. Market Forecasts and Growth Opportunities

Looking ahead, the chip adjustable resistor market is poised for continued growth. Market forecasts indicate that the demand for these components will rise, driven by advancements in technology and the proliferation of smart devices. Emerging applications in sectors such as renewable energy systems and advanced automotive technologies, including electric vehicles, present significant growth opportunities for manufacturers.

B. Emerging Applications and Sectors

The integration of chip adjustable resistors in renewable energy systems, such as solar inverters and energy storage solutions, is expected to gain momentum. Additionally, as the automotive industry shifts towards electric and autonomous vehicles, the need for precise and reliable adjustable resistors will become increasingly critical.

C. Potential Challenges and Barriers to Growth

Despite the promising outlook, the chip adjustable resistor industry faces potential challenges. Supply chain issues, exacerbated by global events, could impact production and availability. Furthermore, competition from alternative technologies, such as digital potentiometers and programmable resistors, may pose a threat to traditional chip adjustable resistors. Manufacturers will need to innovate continuously to stay ahead in this competitive landscape.

VIII. Conclusion

In summary, the chip adjustable resistor industry is undergoing significant transformation, driven by technological advancements, market dynamics, and environmental considerations. The evolution from traditional resistors to chip adjustable variants has paved the way for enhanced performance and integration in electronic devices. As the market continues to grow, manufacturers must prioritize innovation and adaptation to meet the changing demands of consumers and industries alike. The future of chip adjustable resistors in electronics looks promising, with ample opportunities for growth and development in the years to come.

IX. References

1. Academic journals and articles on semiconductor technology and electronic components.

2. Industry reports and market analyses from reputable sources.

3. Relevant websites and publications in the electronics and semiconductor industries, including IEEE, SEMI, and industry-specific trade journals.

This comprehensive overview of the development trends in the chip adjustable resistor industry highlights the importance of these components in modern electronics and underscores the need for continuous innovation to meet future challenges.

2024-11-08

0