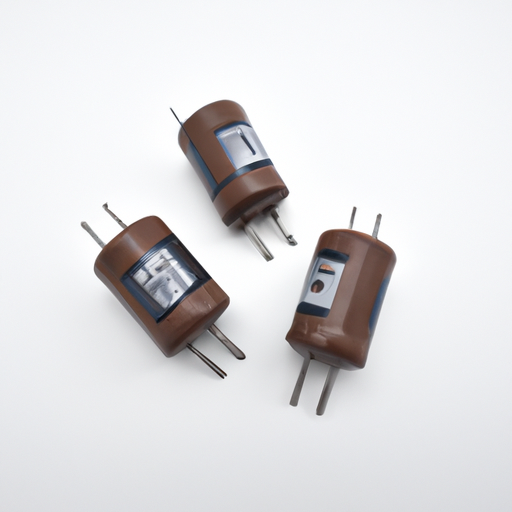

Core Functional Technologies of Film Capacitors

1. Dielectric Material: Film capacitors utilize thin plastic films as the dielectric material, which can be made from various polymers such as polyester (PET), polypropylene (PP), and polycarbonate (PC). These materials provide high insulation resistance and low dielectric losses, ensuring efficient energy storage and minimal energy dissipation.

2. Low ESR and ESL: Film capacitors typically exhibit low equivalent series resistance (ESR) and equivalent series inductance (ESL), making them suitable for high-frequency applications. This characteristic allows for efficient energy storage and discharge, which is critical in applications like RF circuits and power electronics.

3. Temperature Stability: Film capacitors maintain stable capacitance values over a wide temperature range, making them ideal for applications in harsh environments. They are less affected by temperature variations compared to electrolytic capacitors, ensuring consistent performance in diverse conditions.

4. High Voltage Ratings: Many film capacitors can handle high voltage applications, which is essential in power electronics and industrial applications. The CFR-50JB-52-1M1, for example, is designed to operate effectively at high voltages, making it suitable for demanding applications.

5. Long Lifespan: Film capacitors have a long operational life due to their robust construction and resistance to aging. This longevity reduces the need for frequent replacements, making them cost-effective in the long run and ideal for applications where reliability is paramount.

6. Self-Healing Properties: In the event of a dielectric breakdown, film capacitors can self-heal, meaning that the capacitor can continue to function without significant degradation in performance. This feature enhances their reliability and safety in critical applications.

Application Development Cases

1. Power Electronics: Film capacitors are extensively used in power supply circuits, inverters, and converters. Their ability to handle high voltages and currents makes them suitable for applications in renewable energy systems, such as solar inverters and wind turbine controllers. For instance, the CFR-50JB-52-1M1 can be employed in a solar inverter to ensure efficient energy conversion and storage.

2. Audio Equipment: In high-fidelity audio applications, film capacitors are preferred for coupling and bypassing due to their low distortion and high-frequency response. They help maintain audio quality by minimizing signal loss and noise, making them essential in high-end audio amplifiers and speakers.

3. Motor Drives: In industrial motor drive applications, film capacitors are used for DC link applications, where they smooth out voltage fluctuations and provide energy storage. Their high ripple current handling capability is crucial for the reliability of motor control systems, ensuring efficient operation in electric vehicles and industrial machinery.

4. Telecommunications: Film capacitors are used in RF applications, including filters and oscillators, due to their low loss characteristics at high frequencies. They help improve signal integrity and reduce interference in communication systems, which is vital for maintaining high-quality data transmission in modern telecommunication networks.

5. Consumer Electronics: In devices such as televisions, computers, and smartphones, film capacitors are used for decoupling and filtering applications. Their compact size and reliability make them suitable for modern electronic designs, contributing to the overall performance and efficiency of consumer devices.

6. Lighting Applications: In LED drivers and lighting control systems, film capacitors are used to improve power factor and reduce electromagnetic interference (EMI). Their stability and efficiency contribute to the overall performance of lighting solutions, enhancing energy savings and extending the lifespan of lighting systems.

Conclusion

Film capacitors, including the CFR-50JB-52-1M1, play a crucial role in various electronic applications due to their unique properties and advantages. Their versatility, reliability, and performance make them an essential component in modern electronic designs across multiple industries. As technology continues to evolve, the demand for high-performance film capacitors is expected to grow, driving further innovation and application development. The ongoing advancements in materials and manufacturing processes will likely enhance the capabilities of film capacitors, making them even more integral to future electronic systems.